At ERNST, customers have access to a team of highly qualified, experienced employees. Countless crash and test systems from our long-standing company are being employed around the world, many of them for decades. ERNST products are characterized by precision and longevity.

Should a problem arise, ERNST guarantees a short reaction time. In addition, ERNST has years of experience with products from other manufacturers.

On-site service

Our experts are there to assist you. Worldwide, with very short reaction times.

Thanks to a structured network and our ongoing in-house training courses, our customers can rest assured that every ERNST employee is ideally suited to support them on site. Each system is pre-assembled in our own manufacturing facility before being shipped to the customer.

Reassembly at the destination guarantees a smooth process, no matter where in the world.

Development

Our profound, technical understanding as well as our decades of experience in the field of special machine construction enable us to provide sound customer support, from the original idea to the finished product.

We develop and design our systems exclusively ourselves and allow our customers to participate on a permanent basis, so that their experience and feedback can also be incorporated into the development process.

Repairs

Despite the highest quality of the products and great care on the part of the customer, malfunctions and damage can occur, the short-term elimination of which is our top priority in order to enable a seamless test process.

We have all system-relevant spare parts for an ERNST product permanently in stock, so that our team is ready for immediate use if worse comes to worst.

Maintenance and service

The execution of all maintenance and servicing work is an important component of our scope of services. From the inventory to the determination and calculation of maintenance intervals and to maintenance or repair work.

Our service team is always at your side throughout the entire product life cycle, even if this is known to be a very long one at ERNST.

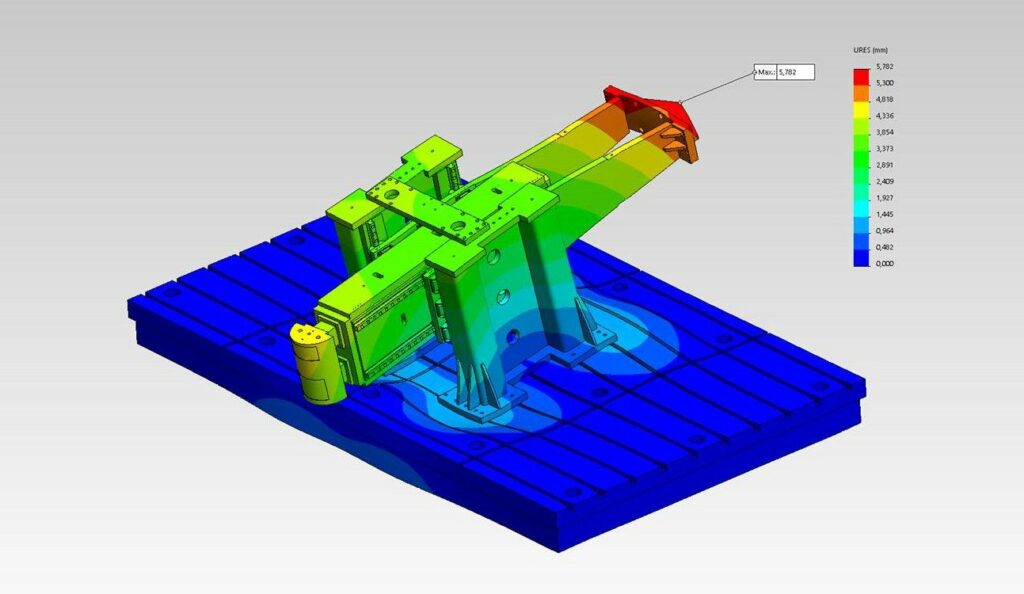

FEM analysis

To advance the optimization of our products, our development team examines existing products or new developments using FEM analyses to raise them to a new level.

In this context, the deformation and vibration behavior of the crash system is determined on a computer basis and targeted optimization options are introduced at the weak points, so that the service life of the products can be increased many times over.

By using the FEM analysis, prototype construction for new developments can be reduced to a minimum and development costs drastically lowered, which in turn benefits our customers.

Training

Through extensive education and training programs, we explain our products to you down to the smallest detail, so that you can experience maximum added value during daily use.

These actions can take place at the customer’s own company or on-site on ERNST’s premises.

Measuring technology

In order to be able to discuss the disturbance factors for our system at our customers’ premises as well as to integrate special features for the customer into our product, we resort to proven measuring equipment.

This approach makes it possible to exclude the external influence on our products during the test execution in the measurement results.

Even with products that have already been in use for a longer period of time, influences can be filtered out with this measuring equipment and improvement measures can be identified.