Testing of individual components is an essential part of today’s development processes. This includes, among other things, customized component test beds.

In this process, the function of individual components such as transmissions, hybrid engines, generators, climate compressors, vibration dampers, cardan shafts and brakes is tested under a wide range of conditions.

The continuously increasing complexity is a great challenge, especially for manufacturers of sophisticated components.

Shortened development phases are countered by increasing requirements in terms of reliability, cost reduction and efficiency.

ERNST has developed a core competence in this area over many years with individual solutions of test bed mechanics. Customers benefit from our own design as well as in-house manufacturing and installation at ERNST.

Drawings

Properties

- Customer-specific design

- Design incl. CAD and FEM simulation by ERNST

- Turnkey solution by ERNST

- Base frame as a welded steel structure

- Vibration damping system

- Climate application

Product examples

Gearbox test bed for running-in cycle

Technical data:

- Speed range: up to 12.000 rpm

- Torque range: up to 100 Nm

- Mass: approx. 1.3 t

- Dimensions: approx. 1.6 m x 0.8 m x 1.6 m

- Functional testing and bearing running-in of engines

- Powertrain consisting of E-motor, coupling, torque meter, coupling and intermediate bearing

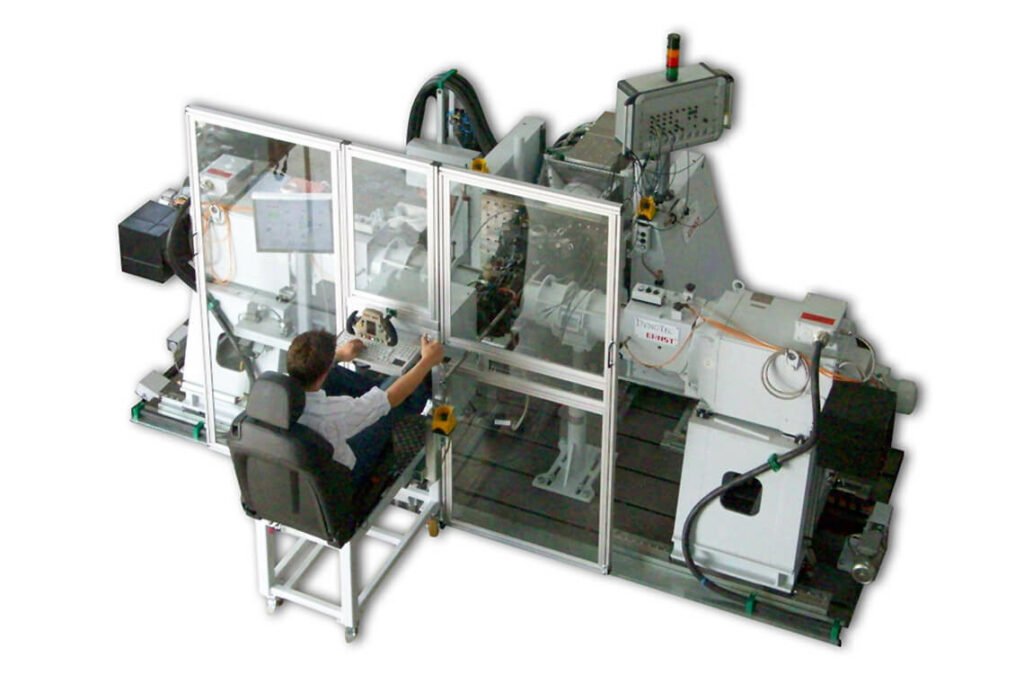

Gearbox test bed for motor sports

Technical data:

- Speed range: Input up to 12.000 rpm | Output up to 3000 rpm

- Torque range: Input up to 400 Nm | Output up to 1200 Nm

- Power: Input 250 kW | Output 2 x 100 kW

- Dimensions: approx. 4.0 m x 3.0 m x 2.1 m

- Optimization and tuning of motor sports transmissions

- Driving simulation, incl. manual shifting system

- Powertrain consisting of K&A input dyno, HBM torque meter, coupling, intermediate bearing, DUT drive, HBM torque meter, clamping element, output dyno

Lubrication test bed

Technical data:

- Speed range: up to 6000 rpm

- Torque range: up to 630 Nm

- Power: 115 kW

- Mass: approx. 2.0 t

- Dimensions: approx. 2.3 m x 0.9 m x 1.5 m

- Determination tribological properties of lubricating oils

- Lubricantion to the test discs via hydraulic unit

- Powertrain consisting of Siemens dyno, clamping element, cardan shaft, clamping element, intermediate bearing

- Force sensor on bearing housing to determine the rolling friction

Any questions?

Apply to us!

We support you in your project.