Back-to-back (B2B) setups provide a good introduction to testing electric motors. The electric motor to be tested (DUT = device under test) is usually coupled with an identical machine and run against each other.

One machine is in torque control mode, while the opposite DUT is in speed control.

The mechanical system has a high stiffness, which excludes natural frequencies within the speed range and guarantees low-vibration operation.

Both the mechanical structure and the shaft connection are manufactured in-house, which provides maximum flexibility for the customer.

Drawings

Properties

- Base structures with 1st natural frequency above the speed range

- Damping elements for vibration decoupling

- Alignment via load elements and grinding plates

- Functional surfaces for retrofitting of bearing points and sensors

- Mounting fits / bolts for mounting of DUTs

- Customer-specific adaptations possible

- In-house production and assembly at ERNST

Options

- Climate preparation

- Mineral cast filling for additional damping

- Shaft connection

- Adaptation components

- B-side support

Product examples

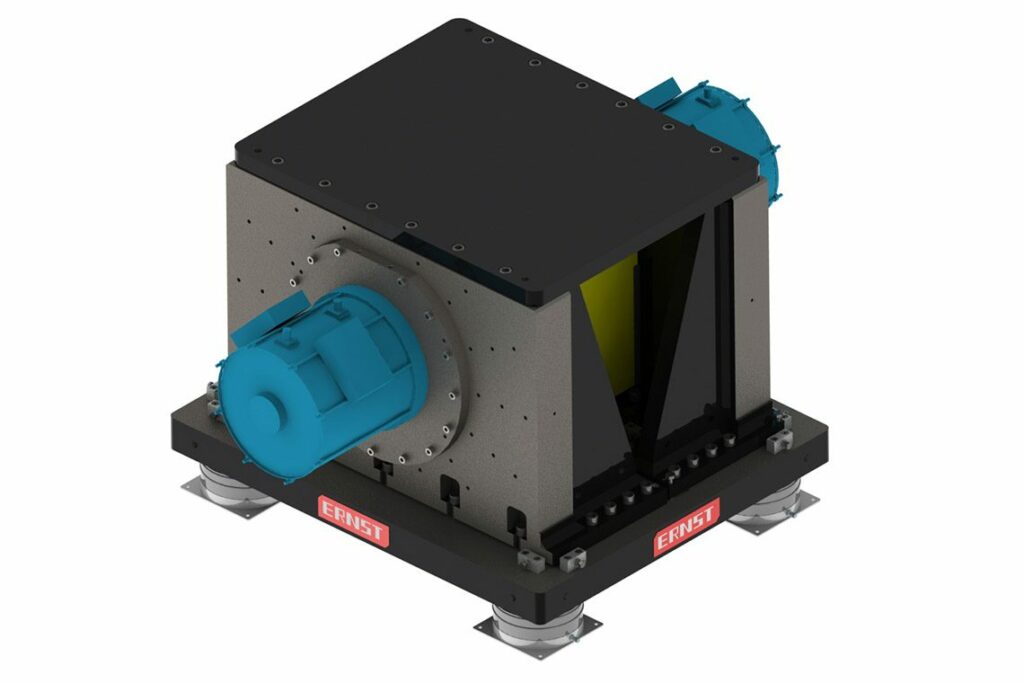

E-motor B2B test bed 20,000

Technical data:

- Speed range: up to 20,000 rpm

- Torque range: up to 1,000 Nm

- Weight: approx. 1,500 kg

- Dimensions: 800 mm x 950 mm x 750 mm

- Shaft connection consisting of two intermediate bearings, HBM measuring flange and coupling

- Mechanical interface identical on both sides

- Large and flexibly applicable adaptation surfaces

E-motor B2B test bed 25,000

Technical data:

- Speed range: up to 25,000 rpm

- Torque range: up to 1,000 Nm

- Weight: approx. 1,600 kg

- Dimensions: 900 mm x 1100 mm x 675 mm

- Shaft connection consisting of an intermediate bearing and shaft adapter, without HBM measuring flange (but adaptation surfaces corresponding to HBM T12HS)

- Mechanical interface identical on both sides

- Large and flexibly applicable adaptation surfaces

E-motor B2B test bed 30,000

Technical data:

- Speed range: up to 30,000 rpm

- Torque range: up to 600 Nm

- Weight: approx. 1,500 kg

- Dimensions: 850 mm x 1220 mm x 700 mm

- Shaft connection consisting of an intermediate bearing and shaft adapter as well as HBM measuring flange (T12HS)

- Milling groove for HBM stator integrated in the substructure

- Mechanical interface identical on both sides

- Large and flexibly applicable adaptation surfaces

Any questions?

Apply to us!

We support you in your project.