Depending on the application, two (or four in 4-E-driveline testing) dynos are used to test individual drive axles and entire drive trains.

The testing of entire drive systems with regard to the interaction of individual components as well as the coordination of the components with each other is an essential part of today’s development processes.

In recent years, ERNST has specialized in customer-specific solutions in this area and, as a system supplier, is able to manufacture the complete mechanics of such systems.

This includes the design as well as the entire mechanical processing up to the in-house installation.

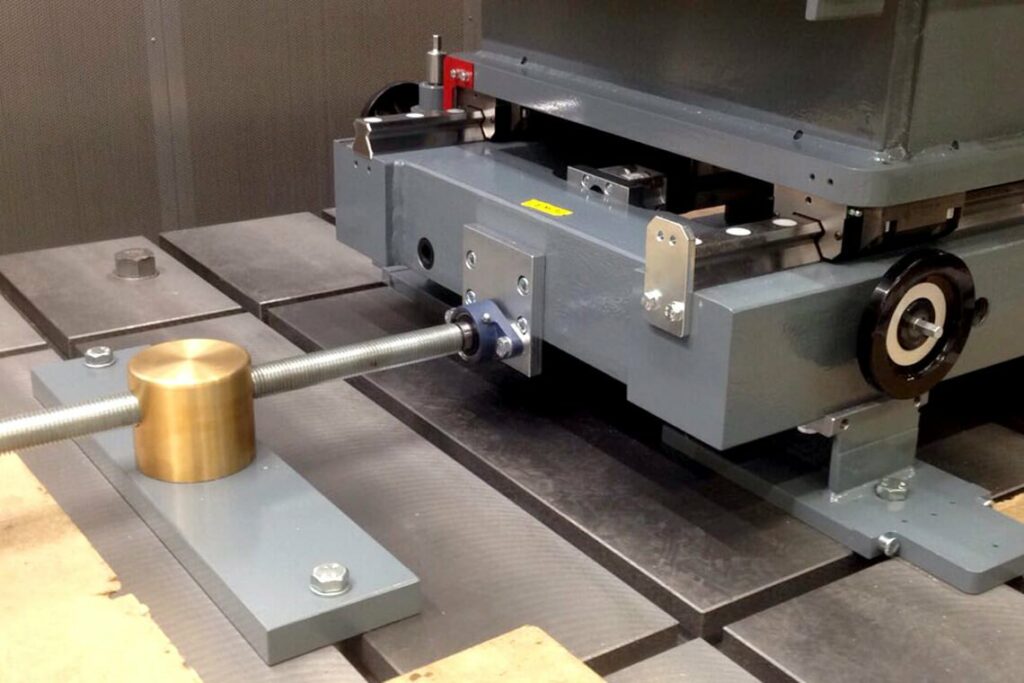

The setup varies from rigid machine frames with base mounting to adjustable base structures. Both the track width and the wheelbase can be continuously adjusted here.

Drawings

Properties

- Customer-specific design

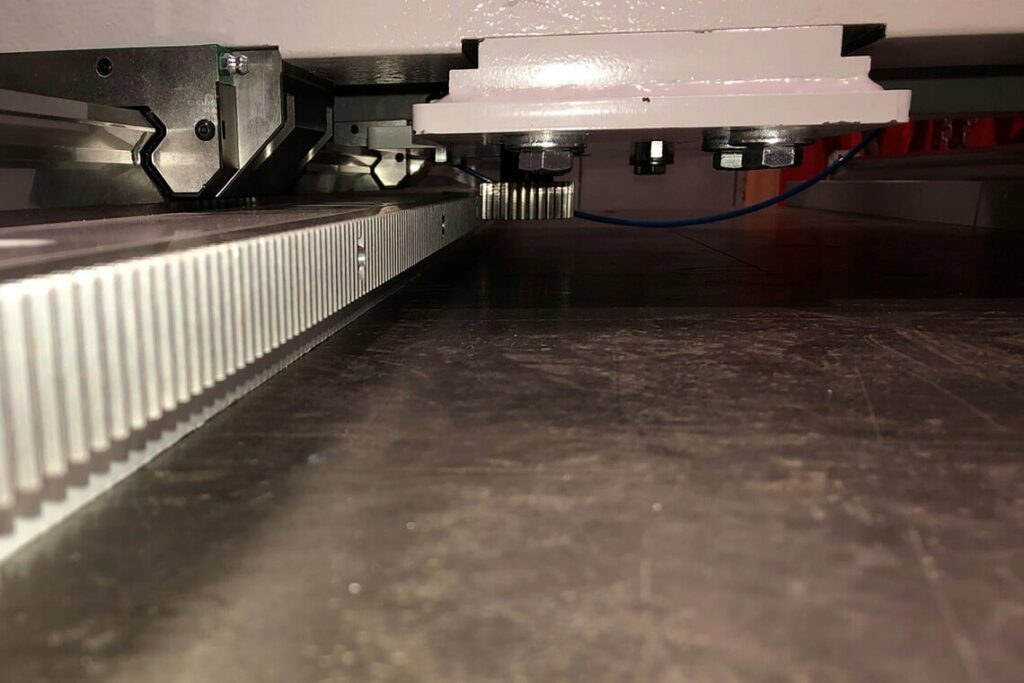

- Track width setting via linear guides

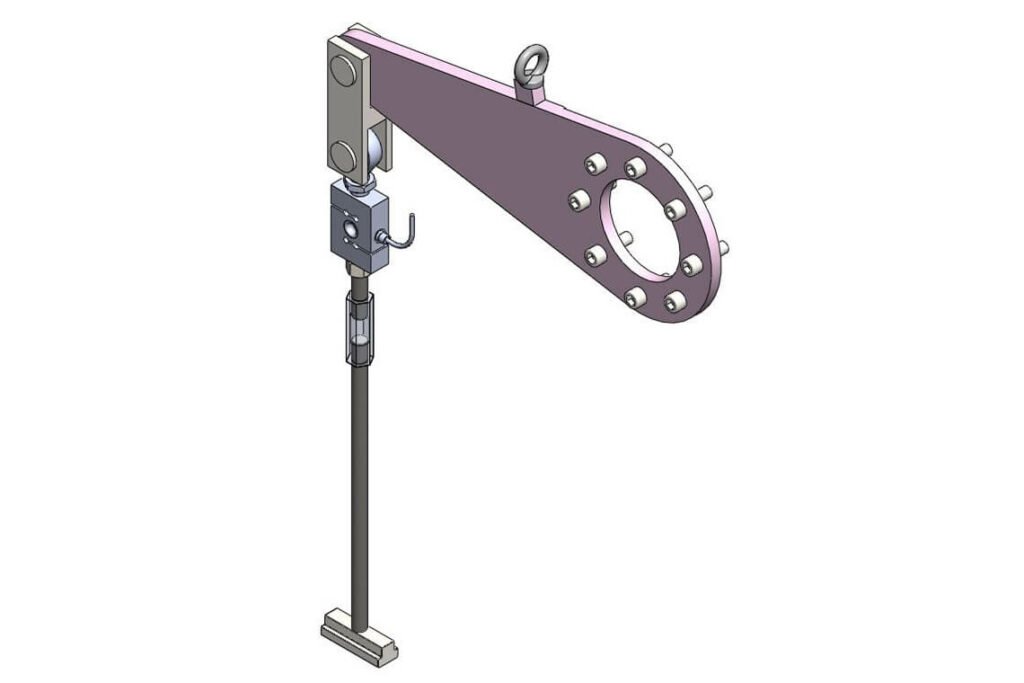

- Overload protection due to safety couplings

- 3D cable chains

- Pneumatic clamping elements

- Customer-specific adaptation

- Turnkey solution by ERNST

Product examples

PSA 2-E-PST, incl. wheel base adjustment, flywheels and shaft guard

Technical data:

- Speed range: up to 2800 1/min

- Torque range: up to 3000 Nm

- Power: 540 kW

- Vibration monitoring

- Extended wheel base adjustment

- OPTION: Wheel base setting

- OPTION: Track width setting via linear quides

- OPTION: Flywheels

- OPTION: Shaft guard

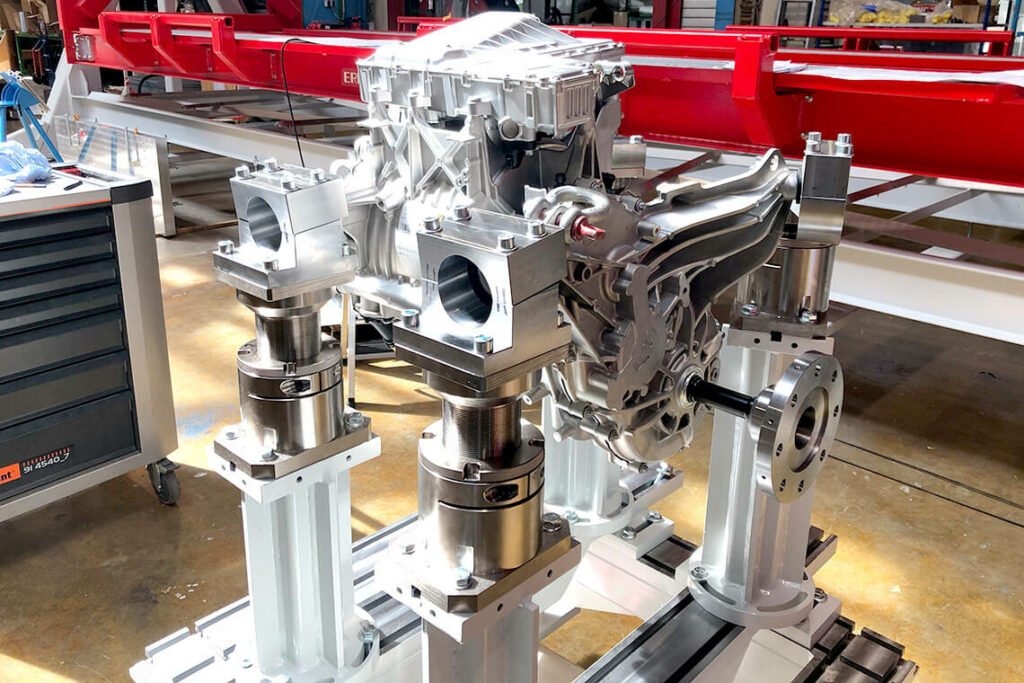

Mahle 2-E-PST, incl. shaft guard, test bed, adaptation and DUT assembly

Technical data:

- Speed range: up to 3000 1/min

- Torque range: up to 4200 Nm

- Power: 420 kW

- Vibration monitoring

- Overload protection due to safety couplings

- OPTION: Shaft guard

- OPTION: DUT palett

- OPTION: DUT adaption

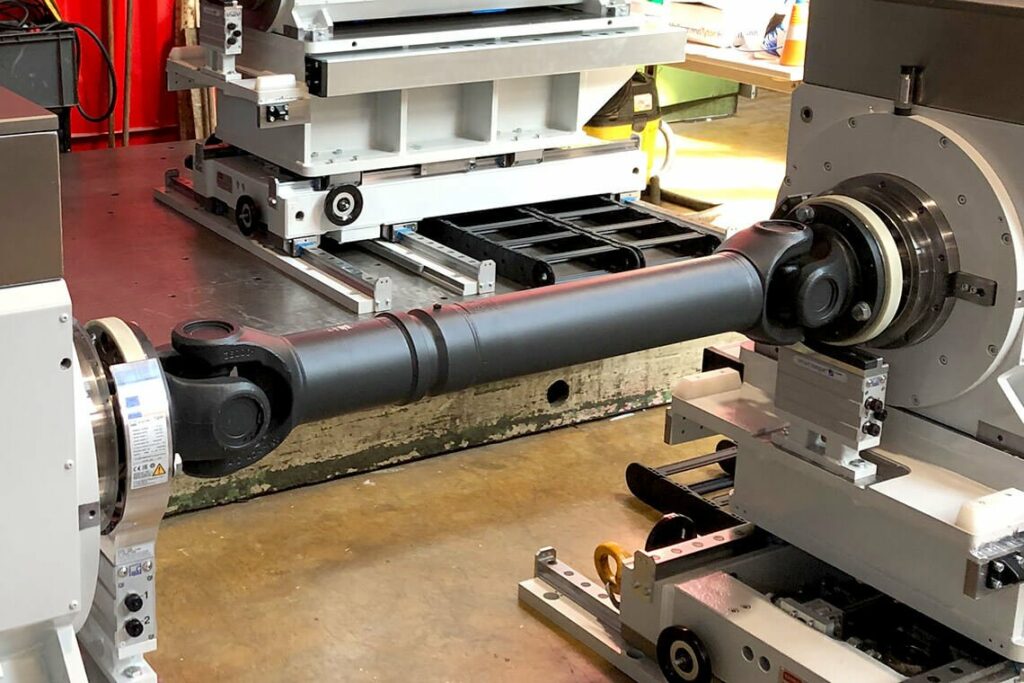

- OPTION: Cardan shaft

Bertrandt 4E-PST, incl. wheelbase adjustment, shaft guard and cardan shaft

Technical data:

- Speed range: up to 3000 1/min

- Torque range: up to 4800 Nm

- Power: 480 kW

- Vibration monitoring

- Divided spanfield

- Two configurations: 4-E-operation or 2 x 2-E-operation

- OPTION: Wheel base setting

- OPTION: Track width setting via linear guides

- OPTION: Shaft guard

- OPTION: Cardan shaft

Powertrain testing in use

Any questions?

Apply to us!

We support you in your project.