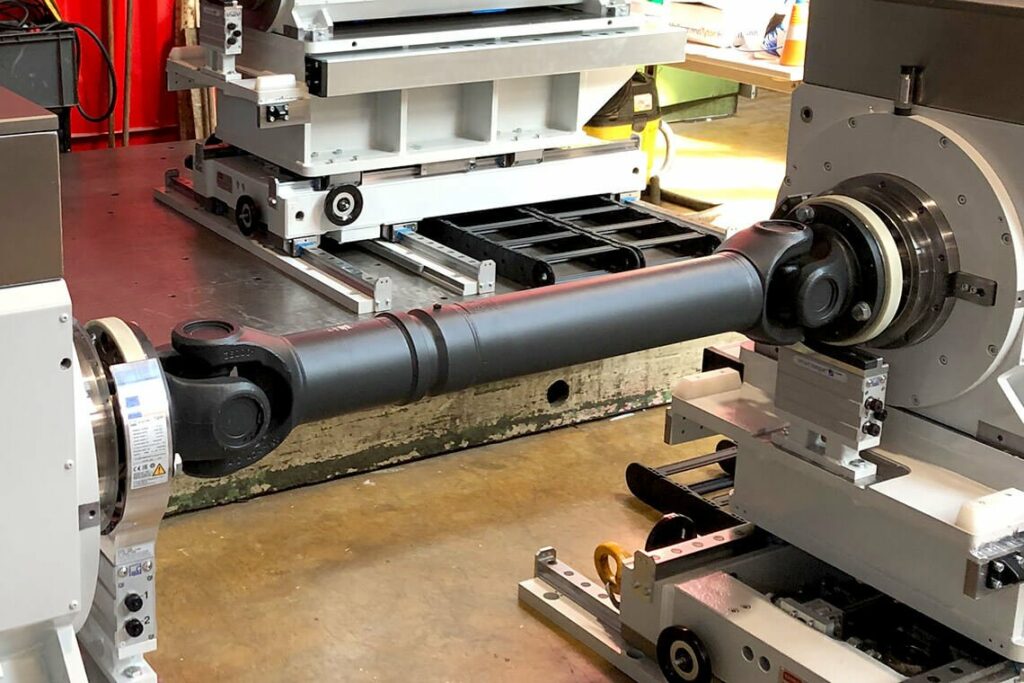

Testing complete vehicles comes closest to the conditions on the road and offers the advantage of being able to test a wide range of situations and processes in-house. Complex international test runs can thus be simulated in advance.

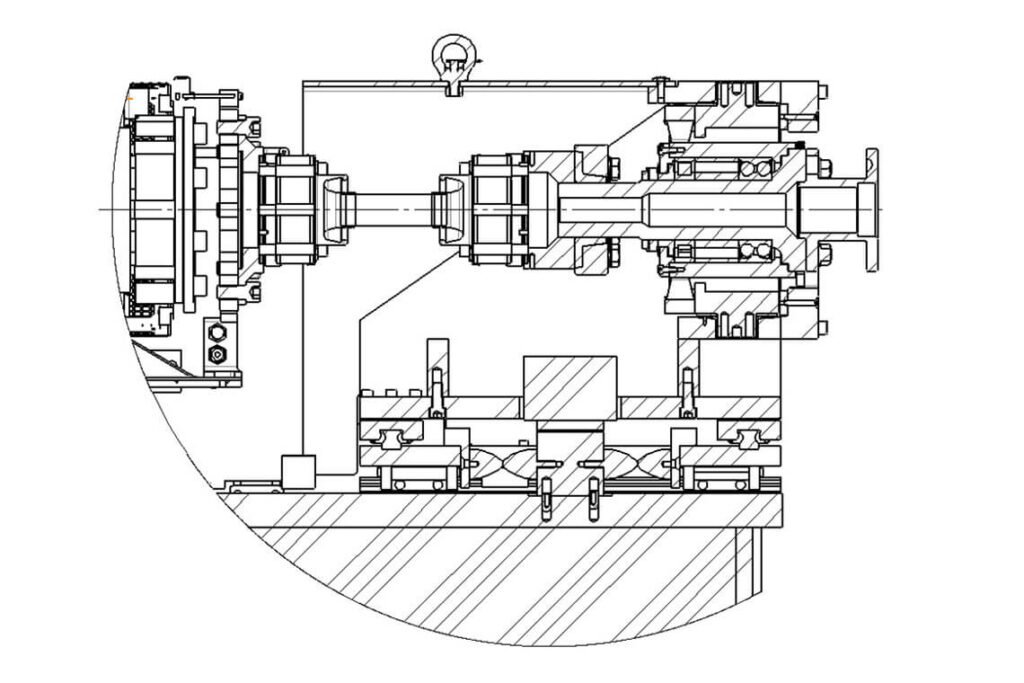

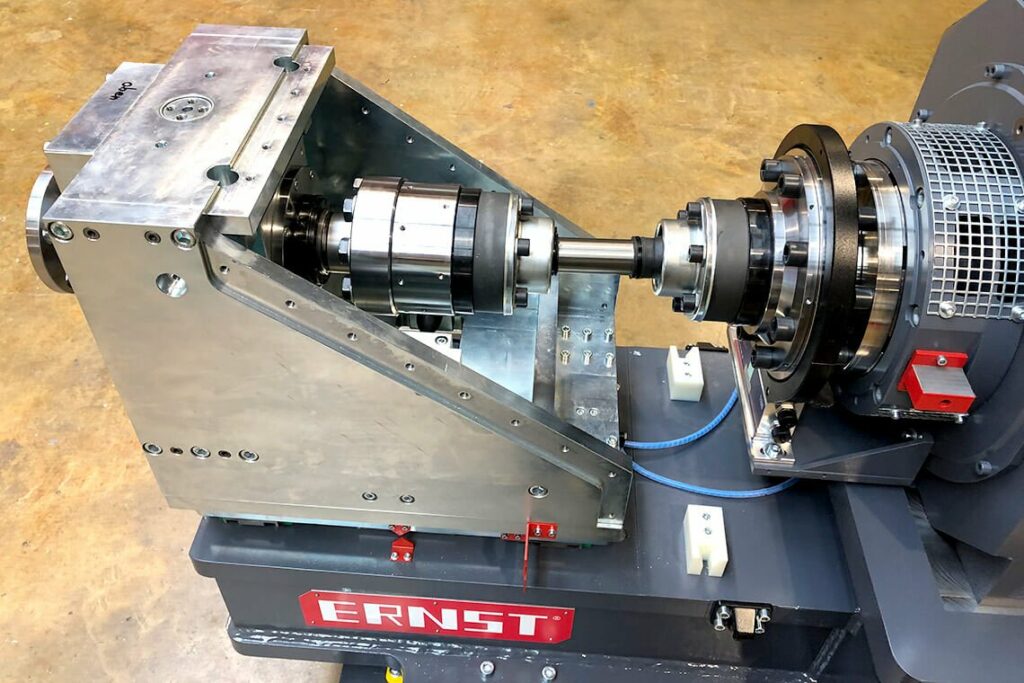

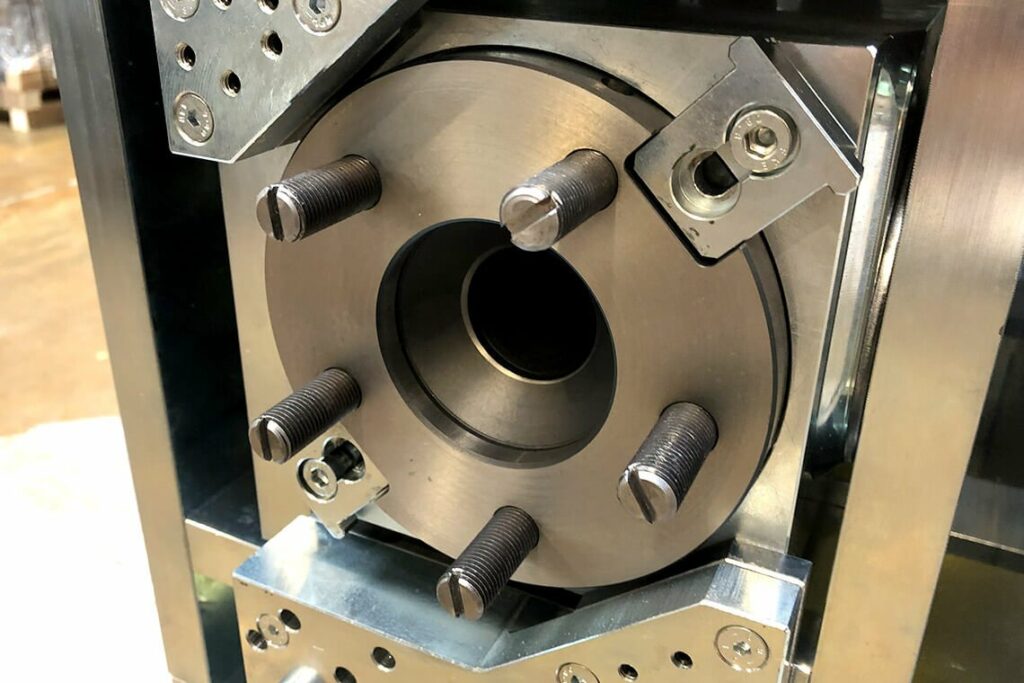

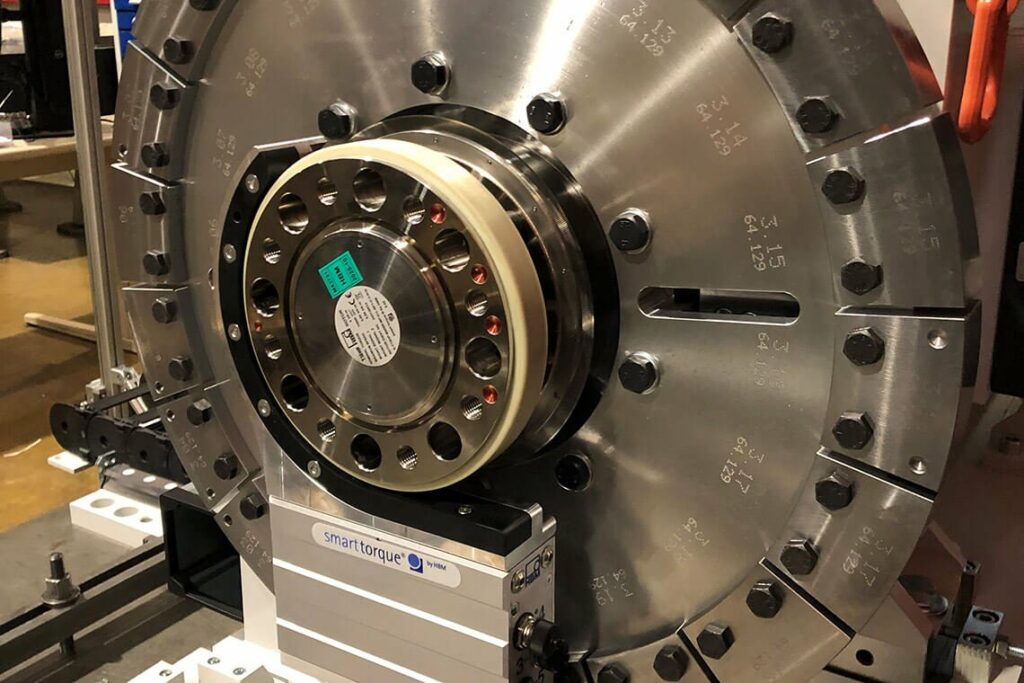

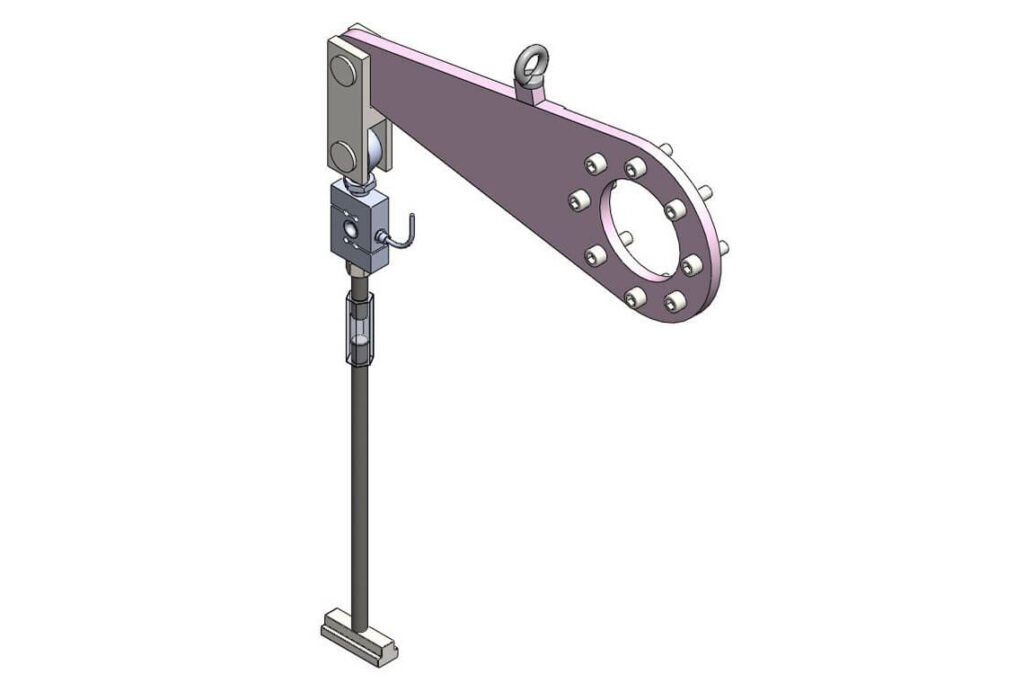

At the heart of such a testing system are the four dynos, each of which is connected to one of the vehicle’s wheel hubs. Thus, all drive train components are tested in interaction with the suspension and vehicle software. In contrast to exclusive powertrain test beds, our vehicle test beds are equipped with a so-called cardan bearing, which hold the vehicle load.

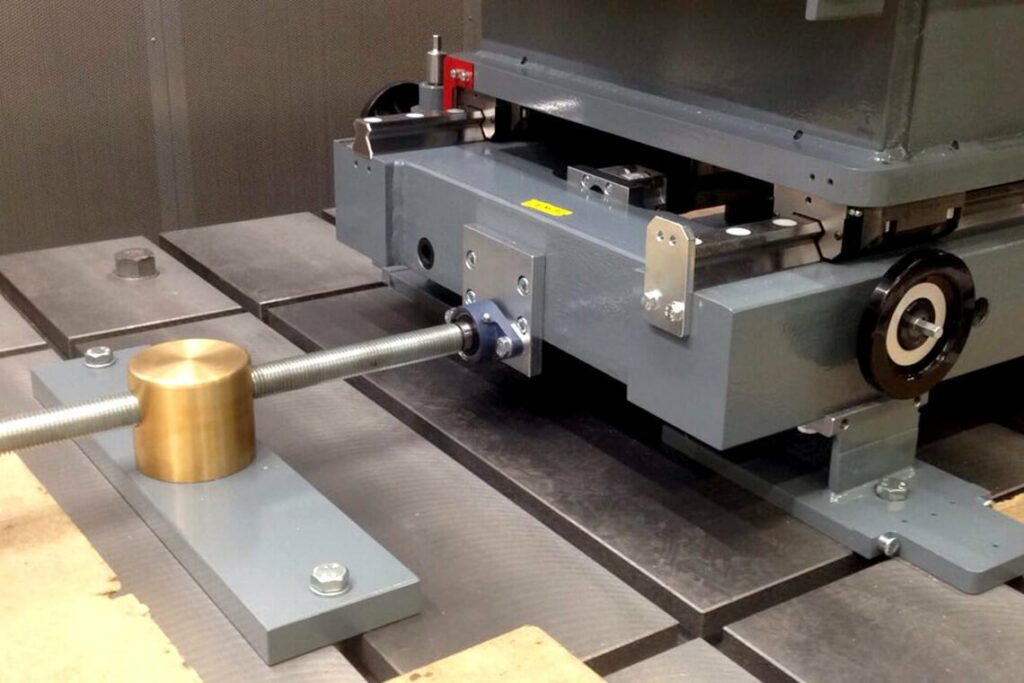

To facilitate installation, the cardan bearing can be moved in the horizontal plane and also turn in two axial directions.

The cardan bearing is continuously fixed with the aid of pneumatic clamping elements, and the resulting angular offset in the shaft train is compensated for by means of a constant velocity cardan shaft.

Furthermore, pre-tensioned damping elements on the Cardan casing ensure vibration-reduced operation. In recent years, ERNST has specialized in customer-specific solutions in this area and, as a system supplier, is able to manufacture the complete mechanics of such systems. This includes the design as well as the entire mechanical processing up to the in-house installation.

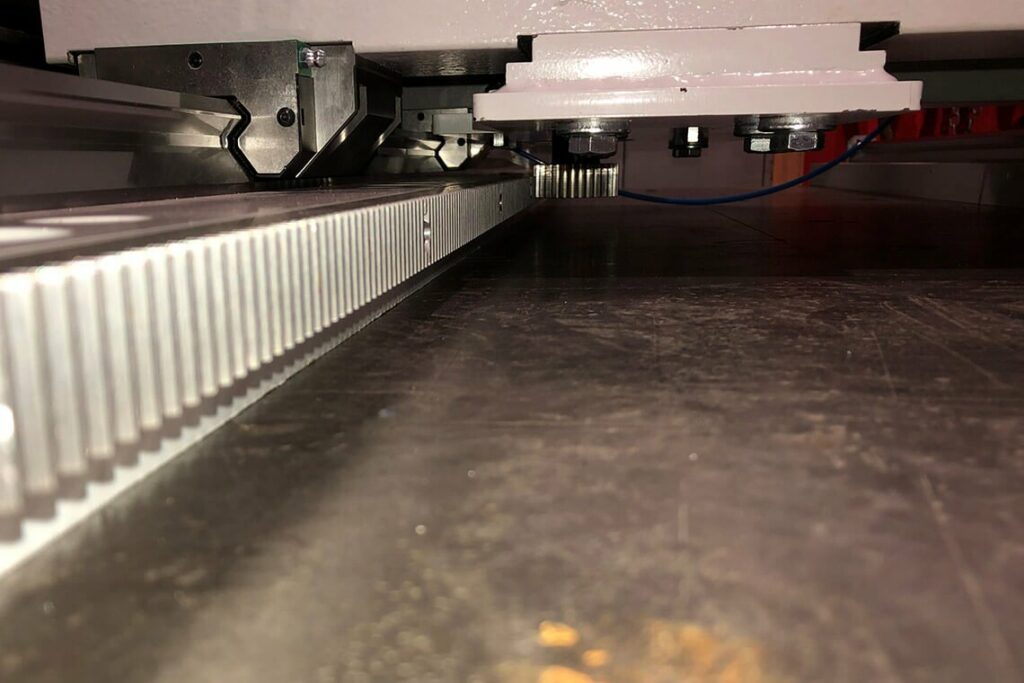

The design varies according to the desired dimensions as well as the dynos used and the required performance data. As a rule, both the track width and the wheelbase can be continuously adjusted here.

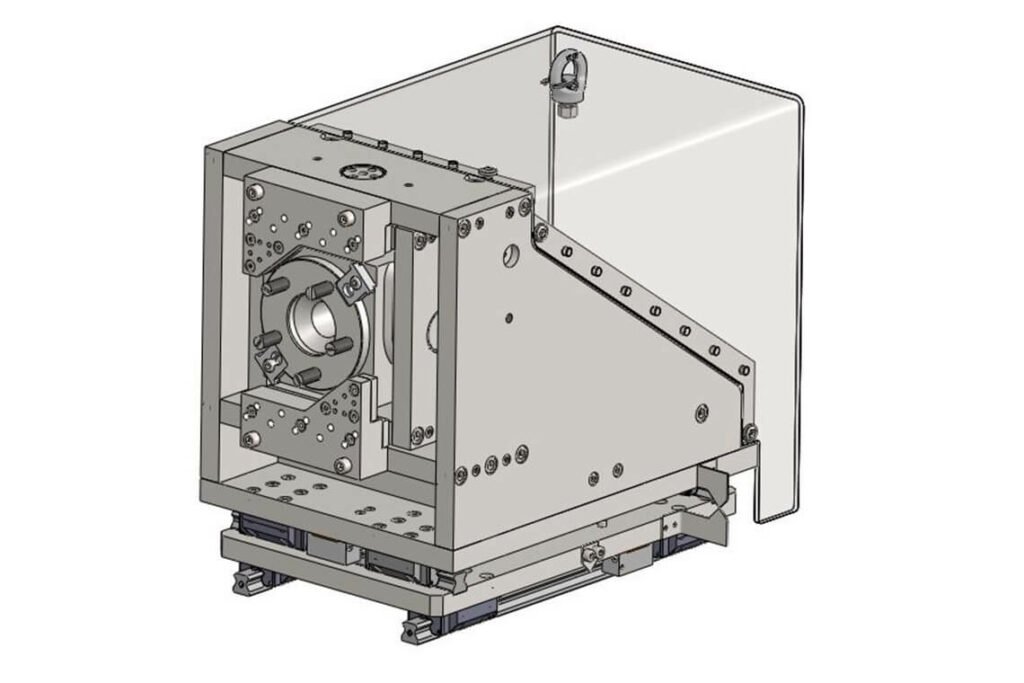

Drawings

Properties

- Customer-specific design

- Cardan bearing for vehicle testing

- Overload protection due to safety couplings

- 3D cable chains

- Pneumatic clamping elements

- Turnkey solution by ERNST

Options

- Flywheels

- Shaft guard

- Wheel base setting via linear guides

- Track width setting via linear guides

- Wheel hub adapter

Product examples

Vehicle test beds in use

Any questions?

Apply to us!

We support you in your project.